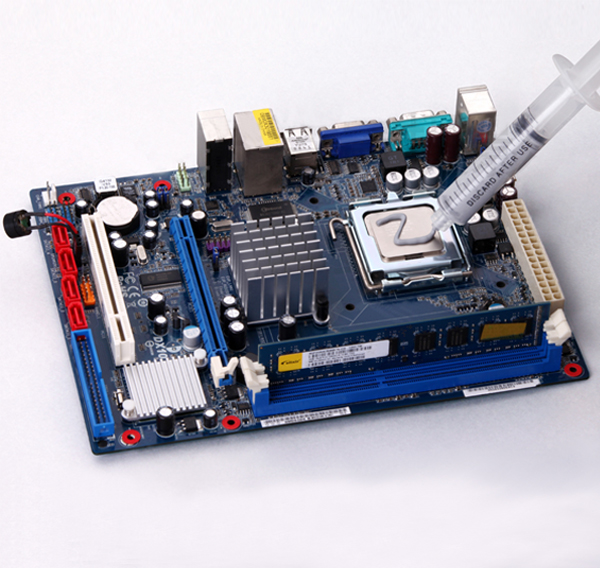

Thermal Grease

Thermal Grease is used in high performance CPU’s and GPU’s. With a high thermal conductivity of 1.5-6W/mK, TG series thermal grease thoroughly wets out thermal surfaces to create very low thermal resistance.

Thermal Grease is used in high performance CPU’s and GPU’s. With a high thermal conductivity of 1.5-6W/mK, TG series thermal grease thoroughly wets out thermal surfaces to create very low thermal resistance.

Thermal grease eliminated the migration issues of silicone based grease to create superior reliability. TG series is ideal for situations where automatic dispensing and screen-printing are required.

TG series is non-toxic and environmentally safe. TG series is available in 2kg(1L container), 8kg (1 gallon) and 20 kg (5 gallon) or custom package in syringes for automated applications.

Product Features

▪ TG300, 400 offers a high thermal conductivity of 3.0-3,8W/mK while achieving thin bonding line thickness of 0.03mm.

▪ TG100 is coat effective product with 1.5W/mK thermal conductivity

▪ TG400SF offers silicone-free base, ideal for silicone sensitive application.

▪ TG600 offers high thermal conductivity with very low thermal resistance.

Typical Applications

▪ CPUs (Notebooks, Desktops, Servers)

▪ LED Solid State Lighting

▪ GPUs

▪ Northbridge Chipsets

▪ ASICS Chips

|

Performance |

TG150 |

TG300 |

TG400 |

TG400SF |

TG600 |

TEST METHOD |

|

Color |

White |

Grey |

Visual |

|||

|

Base Material |

Silicone |

Silicone |

Silicone |

Silicone-free |

Silicone |

|

|

Viscosity (cps) |

<250,000 |

50,000~150,000 |

<150,000 |

<250,000 |

<250,000 |

Brookfield Viscometer |

|

Density (g/cc) |

2.47 |

2.6 |

2.73 |

2.57 |

2.65 |

ASTM D792 |

|

Flaming Rate |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

UL 94 |

|

Operation Temp.(oC) |

-40~150 |

-40~150 |

-40~150 |

-40~150 |

-40~150 |

—— |

|

Thermal |

||||||

|

Thermal Conductivity (W/m-K) |

1.5 |

3.0 |

3.8 |

4.0 |

6.0 |

ASTM D5470 |

|

Thermal Resistance (in2ºC/W) |

0.045 |

0.025 |

0.022 |

0.021 |

0.018 |

ASTM D5470(20psi) |

|

0.025 |

0.021 |

0.018 |

0.017 |

0.015 |

ASTM D5470(50psi) |

|

|

Shelf life |

||||||

|

Shelf Life@ 25℃ |

12month |

6 month |

6 month |

6 month |

6 month |

—— |

188-2226-7107

TIANJIN BROTHERS TECHNOLOGY CO., LTD.

Tel: 18822267107

Email:gavin.ma@brothers-tech.com

PRODUCTS

PRODUCTS